Veolia & Aquama

STPI, a subsidiary of Veolia Industries Global Solutions, is committed to zero chemicals in the cleaning and disinfecting products used on its customer sites.

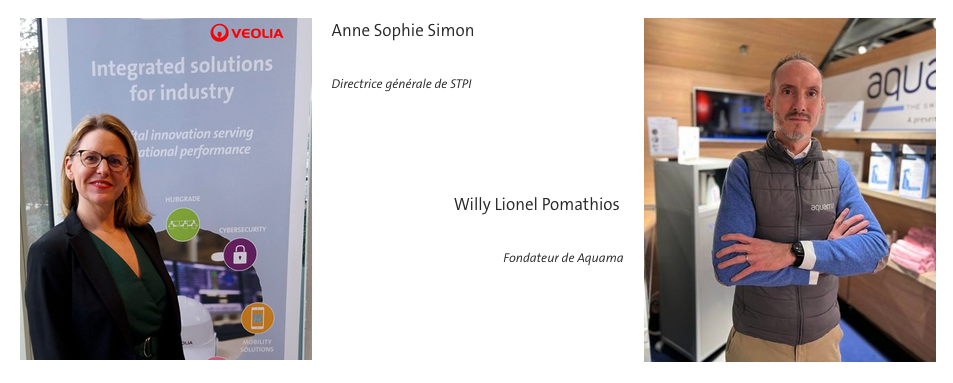

When Veolia, the world leader in ecological transformation, meets Aquama, a Swiss technology scale-up: a cross-interview with Anne Sophie Simon, Managing Director of STPI, a Veolia subsidiary dedicated to multiservice in industry and the service sector, and Willy Lionel Pomathios, founder of Aquama.

Anne Sophie Simon

At first glance, the link between the world of cleaning and the ecological transition may not seem immediate, but it's a direct one, and STPI understands this. Everywhere in the world, cleaning activities lead to the discharge of tons of polluting chemical residues into the environment. Every spray, every wipe pollutes.

Even though we long ago switched to eco-labeled or bio-sourced products, the impact of their production, transport across the planet and single-use plastic packaging still weighed too heavily on our carbon footprint. We wanted to go further.

When we renewed one of our contracts, we wanted to offer a 100% eco-responsible solution. After careful industrial monitoring, Cyril Camboulin, our methods engineer, identified Aquama and its 0 chemistry solution.

Willy Lionel Pomathios

Aquama is a Swiss company, so when Veolia came to us 3 years ago, we were already established in Geneva, with contracts with the city, the international airport and the Swiss Olympic Committee. To be approached by such a large group made us very proud. We were immediately on the same wavelength.

I founded Aquama when my son was born, to have an impact on the world he would live in. Very quickly, cleaning products appeared to be a major source of pollution, with few alternatives. Numerous studies have demonstrated the high level of pollution in the air inside homes and offices. Up to 900 chemical substances, some of them highly carcinogenic, are found in domestic wastewater and then in the natural environment in the form of micro-pollutants.

This is where I wanted to take action.

“Produce an all-in-one eco-detergent, on site, on demand”.

Our detergent is chemically neutral for the environment, and is manufactured using water, salt and electricity. The process consumes very little energy. It's an all-in-one disinfectant, cleaner, bactericide and virucide for cleaning all types of surfaces. It meets numerous standards, including EN16777 (surface virucide), EN1500 (hand disinfection) and EN 14476:2019-10 Coronavirus. Once manufactured, it retains its properties for 6 months.

It offers a 0-pollutant alternative for 99% of the cleaning products used in professional and private environments. Our customers include hospitals, crèches, restaurants, airports and .....

“Aquama, an eco-system for eco-sharing”.

Our solution is a model that is revolutionizing the cleaning market. We don't sell a product, we sell an ecosystem. It includes machines for sale or leasing that produce detergent on the spot and on demand, as well as an application where owners can declare themselves to be eco-sharers or local retailers.

Some resell the product to the general public, like the Manor chain of stores in Geneva, the equivalent of Galeries Lafayette, while others, like Geneva airport, become suppliers to local companies. It's a new way of meshing a region with a household product made locally, without factories, without transport, without disposable plastic containers - a truly virtuous global balance sheet.

Anne Sophie Simon

In terms of health and safety in the workplace, we were reassured by the innocuousness of the solution, which ticked a decisive box for us: the protection of our teams. Aquama does not irritate eyes or skin, does not cause allergic reactions, and presents no risk if swallowed. We were 100% in line with our prevention policy.

“A 0-pollutant alternative that protects Veolia teams”.

.jpg)

All this really convinced us, and we integrated this offer. It marks a radical shift in the world of waste management. Why radical? Because this offer is a new way of looking at our business.

We have a multiplied impact on the chemical, carbon and plastic waste balance sheet of Veolia and our customers.

It's a new invoicing model, with monthly flat rates regardless of volumes produced. In this way, we optimize the machines already installed to supply our nearby sites.

It's a short circuit, because the solution is produced on site by our teams and can be delivered to nearby sites in 1000-liter tanks. Transport distances are reduced from several thousand kilometers to just a few dozen.

“Our ambition: 100% of STPI contracts to go to 0 chemicals”.

Finally, it's an integrated offer available on all our contracts. This partnership is not a marketing operation to obtain yet another green label; it is an integral part of Veolia's raison d'être. Our approach is proactive, and our aim is to get 100% of our customers on board towards 0 chemicals. We're the only company in our sector to have gone this far.

In 2 years' time, we'll have completed our nationwide coverage so that we'll be able to serve all our customers, i.e. with a fleet of machines capable of producing up to 540,000 liters of Aquama solution per year.

Today, the solution is 100% deployed at the ITER site in the south of France, at the Volvo sites in Blainville and Lyon, and 50% at Naval Group's industrial sites. We'll soon be starting up Stellantis in the east of France. A great success!

To support this changeover, we are also carrying out communication campaigns aimed at customers, occupants and employees, to help them make the smooth transition to the Aquama solution.

Willy Lionel Pomathios

These communications operations are essential. In the world of cleaning, we have a critical obstacle to overcome: the lack of scent in our product. However, advertising encourages the general public to associate cleanliness with a fragrance, be it lavender, pine, fresh... This is true for building occupants, but also for maintenance staff. Perfume is a guarantee of a job well done. We must never neglect this psychological aspect, or risk missing out on an implantation.

Anne Sophie Simon

That's why we've worked hard on this aspect.

On the customer's side, we involve stakeholders at a very early stage, with on-site test phases and progressive installation. Specific signage is installed during testing to explain the approach and the benefits of the product. We also carry out post-test surveys among occupants to gather their feedback - in short, we evangelize to convince.

As for the employees, they receive training on the machines used to produce the detergent, and are made aware of the benefits for their health and the environment. Finally, in the 1st phase of implementation, we equip them with essential oil sprays for a smooth transition to 0 perfume.

It's a complete change of management paradigm.

“STPI, the driving force behind Veolia's green cleaning proposals”.

We have a great roadmap ahead of us to make STPI the leader in ecological industrial and tertiary cleaning. Cyril Camboulin and his team, with the support of the Aquama teams, are now focusing their research on rainwater recovery and its use in detergent production. This could save 540,000 liters of drinking water.

At the same time, contacts are being made with other Veolia subsidiaries to integrate them into our ecosystem. We're thinking in particular of our waste management activities, which use a lot of water and products to wash and disinfect their trucks and other facilities.

It's exciting and we're proud that this project is 100% led by STPI, a subsidiary of Veolia Industries Global Solutions. It offers significant gains for us, for the group, for our customers in the collective reduction of our environmental footprint.